Birthday Cake Base Supports: Key Structural Design Considerations for Supporting Over 10kg

In the European and American baking industry, large multi-tiered birthday cakes and custom-themed birthday cakeshave become a core product for bakeries and event planning companies. These cakes often weigh over 10kg, and the structural design of their base support directly determines the safety of transportation, display stability, and food safety. For European and American buyers, a standard-compliant, high-load-bearing birthday Cake Base support needs to meet stringent load-bearing requirements, as well as comply with food contact safety regulations, environmental principles, and practical usage scenarios. This article will delve into the key structural design considerations for birthday Cake Base supports weighing over 10kg, providing professional reference for global baking industry buyers.

I. Core Design Principles for 10kg+ Birthday Cake Base Supports

The design of high-load-bearing birthday Cake Base supports must revolve around four core principles: "safety, stability, compliance, and practicality." These are also key evaluation dimensions for European and American market buyers when selecting suppliers.Safety and Compliance First: Must comply with European and American food contact material standards, such as FDA certification and EU EC 1935/2004 regulations, ensuring that the materials do not contain harmful substances and are suitable for packaging directly edible foods such as birthday cakes.Structural Stability is Core: A weight of over 10kg places extremely high demands on the base support's resistance to deformation and fracture. The design must ensure even weight distribution to avoid the risk of collapse due to localized stress concentration.Even Load Distribution Design: The cake weight must be evenly distributed to the contact surface through the base support structure. Especially for multi-tiered cakes with off-center weight distribution, the design needs to allow for center of gravity adjustment.Scenario Adaptability: Adaptable to common cake sizes in the European and American markets (8-16 inches), transportation methods (express delivery, cold chain, manual handling), and display scenarios (cake display cases, banquet tables), balancing practicality and convenience.

II. Key Structural Design Points: Comprehensive Optimization from Materials to Processes

1. Base Material Selection: Dual Guarantee of High Strength and Food GradeFor birthday Cake Base supports weighing over 10kg, the base material is fundamental to structural strength. We recommend using the following two types of market-proven materials:High-strength corrugated cardboard composite panels: Made of three or five layers of corrugated core laminated with food-grade cardboard. A-type or C-type corrugated cores are preferred, offering excellent compression resistance and cushioning, and meeting recyclable and environmentally friendly requirements, aligning with the green procurement trends in European and American markets.Food-grade MDF panels (medium-density fiberboard): Moisture-proof treated food-grade MDF panels with a density of ≥700kg/m³, providing stable load-bearing capacity, a smooth surface for easy printing, and suitability for customized display needs of high-end birthday cakes.Note: Regardless of the base material chosen, it must pass SGS food contact safety testing to ensure no release of harmful substances such as formaldehyde and heavy metals.

2. Laminated Structure Design: Strengthening Load-Bearing and Anti-Deformation CapabilitiesA single material is difficult to meet the load-bearing requirements of over 10kg. A scientifically designed laminated structure is key:Cross-laminated process: Using 3-5 layers of cross-laminated construction, with the top and bottom layers made of food-grade kraft paper with strong folding resistance, and the middle layer consisting of a corrugated core or honeycomb core. This utilizes the cross-directional fibers to disperse vertical pressure, increasing the overall compressive strength of the base by more than 40%.Thickened core layer design: For extra-heavy birthday cakes weighing over 12kg, 1-2 layers of high-density corrugated core can be added to the middle layer, forming a five-layer laminated structure of "top layer + cushioning layer + load-bearing layer + cushioning layer + bottom layer," effectively resisting the longitudinal compression caused by the weight of the cake.

3. Edge Reinforcement Process: Eliminating the Risk of Cracking and DeformationThe edges of the base are weak points, especially prone to chipping and bending during handling. Special processes are needed to strengthen them:Rolled edge reinforcement: The edges of the base are rolled 2-3 times, with a rolling diameter of ≥1.5cm, enhancing edge folding strength and preventing sharp edges from scratching operators or cake packaging.Film protection process: The edges are covered with food-grade PP film to improve moisture resistance and prevent softening of the edges due to condensation from refrigerated cakes, ensuring structural stability in environments ranging from -5℃ to 35℃.

4. Anti-Slip and Fixing Design: Adapted to Transportation and Display ScenariosThe European and American markets have extremely high requirements for the safety of cake transportation. The anti-slip and fixing design of the Cake Base directly affects the customer experience:Bottom anti-slip coating: A dotted or striped anti-slip coating is printed on the bottom of the base, with a friction coefficient ≥0.6, effectively preventing the cake from sliding during transportation, and is suitable for various transportation scenarios such as delivery vehicles and cold chain shelves.Cake fixing groove: A circular groove is designed on the surface of the base, with a groove depth ≥0.8cm and a width that matches the bottom of the cake, which can fix the cake and prevent the center of gravity from shifting when multiple layers of cakes are stacked.

5. Size Adaptation Optimization: Matching Mainstream European and American Cake SpecificationsThe size of the Cake Base needs to be precisely matched with the common birthday cake sizes in the European and American markets to avoid uneven weight distribution due to mismatched sizes:Diameter adaptation: For mainstream birthday cakes of 8 inches (20cm), 10 inches (25cm), 12 inches (30cm), and 14 inches (35cm), the diameter of the base should be 2-3cm larger than the diameter of the cake to allow for packaging and handling space.Thickness standard: The thickness of the base for a weight of 10-12kg should be ≥1.2cm, and for 12-15kg, the thickness should be ≥1.5cm, ensuring that the deflection under the weight of the cake is ≤3mm (without permanent deformation).

III. Additional Design Considerations for the European and American Markets

1. Environmental Protection and Recyclability: Aligning with Green Procurement TrendsEuropean and American buyers generally value environmental compliance, and the base design needs to meet the following requirements:Recyclable materials: Priority is given to FSC-certified renewable paper materials to ensure that the entire product can enter the European and American waste paper recycling system.Biodegradable options: For the high-end market, a base with a biodegradable coating can be provided, which can be completely degraded within 6 months in a natural environment, complying with the EU Packaging Waste Directive (94/62/EC).

2. Customized Adaptation: Meeting Branding NeedsEuropean and American baking brands focus on product differentiation, and the customized design of the Cake Base can enhance the added value of the product:Surface printing compatibility: Supports food-grade soy ink printing, allowing for customized brand logos, birthday themed patterns, or instructions for use. The printing accuracy is ≥300dpi and does not affect food safety. Customized Irregular Shapes: For irregularly shaped birthday cakes such as heart-shaped or square cakes, corresponding irregular base trays can be designed. The edges feature a curved transition to ensure even weight distribution and enhance the product's aesthetic appeal.

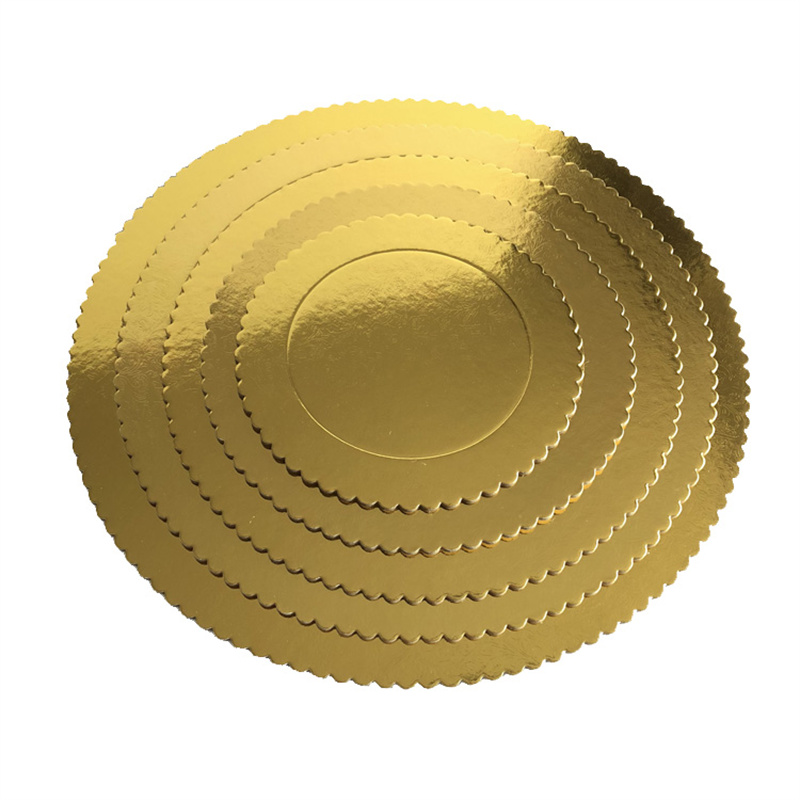

3. Convenient Stackable Storage: Reducing Storage Costs for BuyersEuropean and American buyers have high demands for warehouse space utilization. The base tray design must consider stackability:Nesting Design: Base trays of the same specifications can be nested and stacked. No deformation occurs when stacked to a height of ≥1.2m, saving more than 50% of storage space.Edge Positioning Protrusions: 3-4 positioning protrusions are designed on the surface of the base tray, with a height of ≤0.5cm, ensuring precise alignment of the upper and lower base trays during stacking to prevent tilting.

IV. Testing and Verification Standards for Structural Design

High-load-bearing birthday cake base trays must pass third-party testing recognized in Europe and America to ensure product performance meets standards:Load-bearing Test: 1.5 times the rated load (e.g., 15kg for a 10kg base tray) is applied to the center of the base tray for 24 hours. The base tray deflection is ≤5mm, with no fracture or permanent deformation.Transportation Simulation Test: Transportation vibration testing is conducted according to ISTA 3A standards. After the test, the base tray shows no chipping, the anti-slip coating remains intact, and the cake fixing grooves maintain their structural integrity.Temperature and Humidity Resistance Test: The base tray is placed in a -5℃ refrigerated environment and a 35℃, 85% humidity environment for 48 hours respectively. The base tray strength loss is ≤10%, with no softening or deformation.

ConclusionThe structural design of birthday Cake Base Trays with a load capacity of 10kg or more is a comprehensive reflection of safety, practicality, and compliance. For European and American buyers, choosing a base tray that meets the above design points can not only reduce cake transportation losses but also enhance brand reputation.AOTONG, as a professional manufacturer with 15 years of experience in the baking packaging field, boasts 100+ structural design patents, food-grade material certifications, and cooperation experience with 500+ global customers. Its high-load-bearing birthday cake base trays have passed third-party authoritative tests such as SGS and CNAS, perfectly meeting the stringent requirements of the European and American markets.

Website:https://www.cakeboardbox.com/

Email:diana@ywaotong.com

Whatsapp:+86-15235176896

Media Contact

Company Name: YIWU AOTONG PACKAGING CO., LTD.

Email: Send Email

Country: China

Website: https://www.cakeboardbox.com/