As electronic systems continue to shrink in size while increasing in power density, the need to effectively reduce EMI on a PCB and across enclosure seams has become more important than ever. Conductive gaskets play a crucial role in preventing electromagnetic leakage, improving signal integrity, and ensuring compliance with stringent industry standards. The newly expanded product range introduces multiple material configurations optimized for harsh environmental conditions, vibration resistance, and long-term durability.

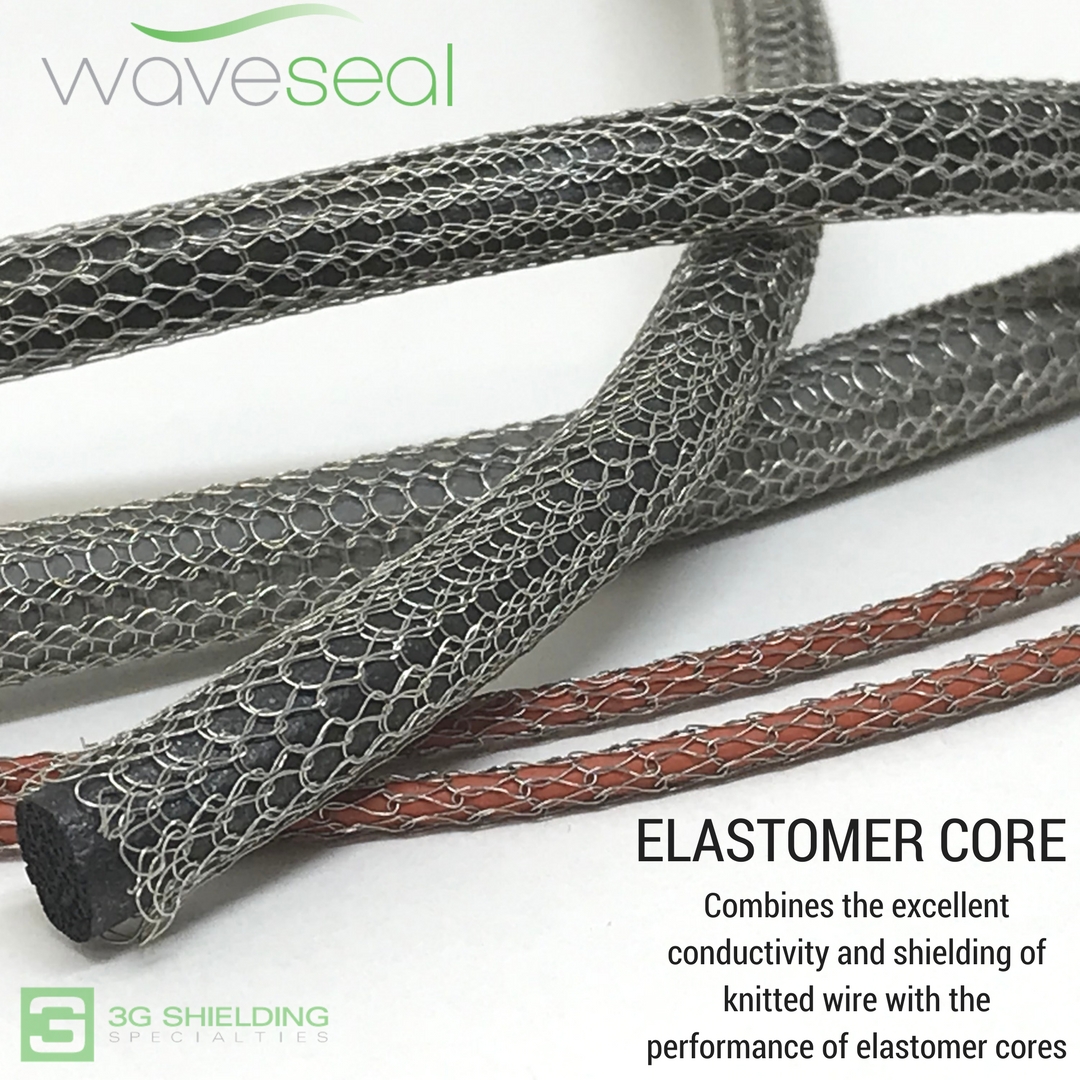

The updated portfolio includes advanced fabric-over-foam gaskets, conductive elastomers, and hybrid conductive elements engineered to provide both mechanical sealing and electromagnetic performance. These solutions are suitable for aerospace, defense, telecommunications, medical devices, and industrial electronics where enclosure shielding and reliability are non-negotiable. By broadening its conductive gasket offerings, the company enables design teams to address a wider spectrum of EMI shielding and RFI shielding requirements without compromising enclosure strength or weight targets.

A growing number of electronics manufacturers are seeking clarity on what a conductive EMI gasket is and how it contributes to overall system performance. Conductive gaskets are specialized sealing components that combine elasticity with electrical conductivity, allowing them to bridge gaps between metal surfaces and maintain continuous grounding paths. This continuous electrical connection is essential for minimizing electromagnetic leakage, reducing unwanted emissions, and protecting sensitive circuitry from external interference. In ruggedized enclosures, these gaskets also provide environmental sealing against dust, moisture, and mechanical shock.

In parallel with gasket development, the company continues to advance integrated solutions that combine conductive elements with microwave absorbers and RF absorbers. These hybrid approaches address both reflection-based shielding and absorption-based suppression techniques, enabling engineers to choose the most effective strategy depending on frequency ranges and application needs. While EMI shielding and RF shielding are often discussed interchangeably, each discipline requires tailored material selection and structural design to achieve optimal performance across diverse frequency bands.

The expanded gasket portfolio aligns with a broader industry movement toward turnkey shielding packages that unify metalwork, absorptive materials, and thermal interface materials into a single engineered solution. Designers increasingly demand shielding systems that not only block interference but also assist in heat dissipation, improve mechanical tolerances, and simplify assembly processes. By offering conductive gaskets alongside microwave absorbers, enclosure shielding components, and thermal transfer materials, the company supports end-to-end design workflows from prototype development to high-volume production.

Another key focus of the expansion is rapid prototyping capability. Engineers working on next-generation electronics often need to test multiple shielding configurations before finalizing a design. Flexible manufacturing systems and short lead times allow prototype gaskets and enclosure shielding components to be produced within days rather than weeks. This responsiveness helps development teams quickly evaluate options such as fabric-over-foam versus conductive elastomer or determine when a microwave absorber is more suitable than a traditional RF absorber.

The growing complexity of electronic ecosystems has also driven interest in best thermal interface materials for electronic cooling, as thermal management and electromagnetic control are increasingly interconnected. Poor heat dissipation can alter electrical characteristics and inadvertently increase interference levels. By integrating thermal and conductive solutions within the same product ecosystem, manufacturers gain better control over both temperature and electromagnetic behavior, resulting in more stable and reliable electronics.

As global demand rises for advanced electronics used in autonomous systems, communications infrastructure, and high-performance computing, conductive gasket technologies and enclosure shielding will remain essential. The expansion of this portfolio reflects a proactive response to evolving design challenges and underscores a commitment to engineering excellence, rapid delivery, and comprehensive shielding strategies. Through continued innovation in EMI shielding, RFI shielding solutions for electronics, and integrated conductive gasket systems, the company positions itself to support the next generation of ruggedized electronic applications across industries.

Media Contact

Company Name: 3G Shielding Specialties

Contact Person: George

Email: Send Email

Country: United States

Website: https://3gshielding.com/